Optimizing Your High Volume Dispensing Systems with Available Features

Choosing a Dispensing System is no small feat. With all of the different features available it can quickly become overwhelming. Here at Dispensing.com we want to give you everything you need to know about High Volume Dispensing Systems, and how to choose the right features for your application.

In this article we will give you a quick overview of all of the dispensing and reservoir options that are available for our top selling dispensing systems. The following options are compatible with our 5 Gallon Drum Dispensing Systems, 55 Gallon Drum Dispensing Systems, High Volume Pump Systems, and All Two-Component Systems. Contact a dispensing.com expert for questions on any of the options and features for high volume dispensing systems.

Dispensing Options

Depending on the type of dispensing you are doing, there are options to help control output and flow of your material. This includes shot timers, spray components and more.

|

Electronic Shot Size Control

- No more overfilling/under-filling parts

- Memory for up to 100 different shot sizes for immediate recall

- Auto Repeat Mode for fast part dispensing, hold down the trigger and dispense across all parts

- Auto solvent purge tank control

- Auto Purge Alarm means no more hard mixers; a built-in timer alerts you when material approaches cure time

- The sequential version of the shot-size controller allows for 100 programs, with each program containing up to 32 steps.

|

|

Spray Systems

- The simple controls system allows an operator to easily achieve a uniform spray pattern

- Double-acting pumps provide an easily controlled continuous flow of material

- Disposable static mixers allow a quick and simple clean up

|

Reservoir Options

Dispensing different materials can mean special requirements for how the adhesives or fluids are stored and dispensed from the reservoir. Dispensing.com offers a full range of reservoir add-ons for high volume dispensing. Whether you need to heat the material, agitate it or keep it free from oxygen, we've got options to help.

|

Vacuum Degassing

- Stainless Steel Body with Tapered Botto for Complete Draining

- Aluminum LId with 2 Tempered Glass Windows for Material Observation

- Can be used for vacuum filling (is vacuum transfer of material from your shipping container)

- Multiple parts in lid

- Available in sizes ranging from 1 to 8 gallons.

|

|

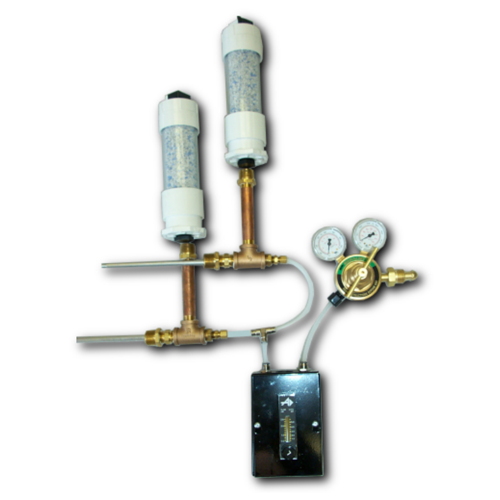

Nitrogen Blanket System

- The regulator/gauge set combined with flow meter allows precise control of nitrogen usage.

- Eliminates moisture damage and extends the storage time of moisture-sensitive materials.

- Reduces maintenance and down-time.

- Can be adapted to all reservoirs and 55 Gallon Drum-feed systems

- Does not include nitrogen tank

|

|

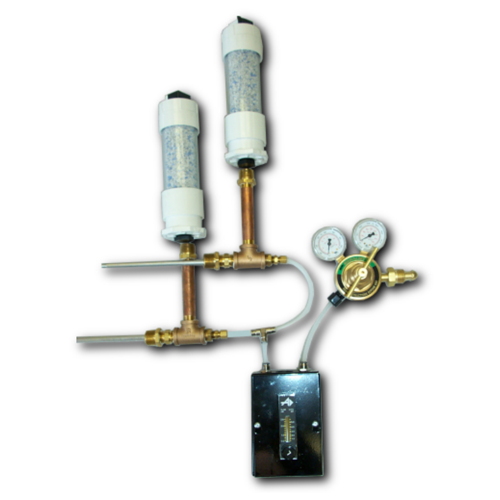

Desiccant Tubes

- For moisture-sensitive materials

- The desiccant mixture contains a moisture indicator that changes from blue to pink when saturated

- Desiccant tubes are refillable. We stock bulk bottles of replacement desiccant for your convenience

- Available with 3/4" or 2" barrel

|

Heating Materials

|

Pump Block Heater

- Available in 100W or 300W

- Available in 110V or 220V

- Available set points of 92°F, 105°F, 115°F, 125°F, 142°F, 160°F and 172°F

- 1/4" mounting holes

- Aluminum construction

- Indoor use only

- Compact design

- Digital temperature controller available as an option

- Thermal fuse protected

|

|

Pump-Base Heater: For Warming Frames and Reservoirs

- 450W 110V

- Adjustable Thermostat

- Warms Frame & Reservoirs through convection

|

|

In-Reservoir Heater

- 300W 110V or 220V

- Aluminum Construction

- Heats the material directly at the point of intake

- Lower energy usage and foster warmup

- Available with a fixed set-point, digital adjustable control, or PID control

- Can be used with Michael Engineering agitators

|

Material Agitators

|

Drum-Feed Flow-Through Agitator

- Enables simultaneous dispense and agitation

- Powered by a pneumatic motor

|

Need Help With Your High Volume Dispensing System?

While the many variables involved may seem overwhelming, by understanding the capabilities available, the perfect high volume dispensing system can be developed quite easily. More information provided at the beginning of a project will minimize the change of any processing issues during the implementation of the equipment. Contact us today to connect with one of our dispensing experts to help choose the perfect set-up to meet your application needs and budget.