- Urethanes

- Epoxies

- Polyureas

- Adhesive Bonding

- Potting and Encapsulating

- Mold Filling

- Rapid Prototyping

- Joint Filling and Sealing

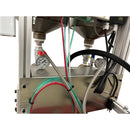

AST GMP 025: Affordable Industrial Benchtop Meter Mix Dispensing System

Streamline Your Industrial Processes with Unmatched Accuracy and Efficiency

Meet the AST GMP 025, an affordable industrial benchtop meter mix dispensing system, meticulously designed for applications such as Rapid Prototyping, Mold Filling, Potting, Encapsulating, and Bonding. This robust and low-cost unit is a workhorse, offering precision and continuous flow, making it a valuable asset for industrial applications.

Common Applications

Rapid Prototyping

The AST GMP 025 ensures consistent and efficient dispensing of materials, making it ideal for creating high-quality prototypes quickly and accurately.

Mold Filling

With its continuous flow and high fluid pressure, the AST GMP 025 is perfect for efficient and precise mold filling in manufacturing processes.

Potting

The system’s precision and adjustable flow rate make it suitable for the potting process, effectively protecting electronic components.

Encapsulating

The AST GMP 025 is ideal for encapsulating applications, providing a secure and protective layer around components due to its precise dispensing capabilities.

Bonding

The precise and continuous flow of the AST GMP 025 makes it a reliable choice for bonding applications, ensuring strong and durable adhesion.

Unrivaled Features & Benefits

- AST GMP Metering Pump: Ensures precise metering for optimal performance.

- Continuous Flow: Achieve up to .25 gpm for efficient operation.

- High Fluid Pressure: Operates at fluid pressures up to 600 psi.

- Versatile Viscosity Handling: Manages viscosities up to 2,000 cps.

- Adjustable Flow Rate & Ratios: Offers ratios from 1:1 to 3:1, allowing customization to meet specific needs.

- Compact & Robust: Features a 1/4 HP 90 volt variable speed DC electric motor, housed in a compact, rugged design.

- Manual or Automatic Dispense Manifold: Provides flexibility in dispensing, handling non-abrasive materials efficiently.

- Cost-Efficient: An industrial, low-cost solution without compromising on quality or reliability.

Specifications

- Model: Small Volume Dispensing, Mold Filling

- Machine Type: Fixed ratio/metering/dispensing GMP gear

- Metering Pumps: (2) heavy-duty AST GMP gearotor™

- Continuous Output: Up to 0.4 gallon per min.

- Viscosity Range: 100 cps to 2,000 cps

- Containers: 2-1/2 gallons each side, stainless steel, 16 gauge

- Dimensions: 21” L x 21” W x 19” D, 100 lbs. empty, shipping weight 150 lbs.

- Frame: 1½” powder-coated tubular steel

- Standard Controls: On/Off; variable speed 12 OV.

- Services Required: 120 V/15 AH, 5 AMP 90 psi, 2 cfm

- Applicators: AST hand-held; automatic dual port manifold

- Mixer: Disposable, plastic, motionless

- Hoses: Teflon core braided stainless steel, 3/8” x 10’

- Options: Heated tanks

Optimized for Industrial Excellence

The AST GMP 025 is not just a dispensing system; it’s a catalyst for enhancing industrial processes, ensuring accuracy, reliability, and efficiency. Whether it’s for urethanes, polyureas, or epoxies, this system is engineered to meet the rigorous demands of any industrial application.

Compatible Materials

- 3M Scotch-Weld DP600

- Ashland 4020

- BASF 37800R

- BASF I 3092T

- Big Dog Adhesives BD9102

- BJB 8004 Urethane

- BJB CF-70AF

- Chemline 2052

- Chemline 8672

- Chemline XCC40419

- Chemline XCC40939

- CIBA Polyurethane 6457

- EFI Polymers 20029

- EFI Polymers 50049

- Epoxyical 9160

- Henkel US5500

- Huntsman 6430

- Hyperlast Por-a-kast Mark 2

- Innovative Polymers RC-82D

- Innovative Polymers RC-350

- Innovative Polymers TD 277-02

- Innovative Polymers TP 4007

- Kalex 45111

- Kalex 55111

- Polyone 33887

- Polyset PC-3287

- Rampf InnoClear OC-5246-3

- Smooth Cast 300

- Smooth-On PMV-790

- SWD Quickshield 450

- Thermoset Solutions ESA 1085

- Thermoset Solutions ESD 1085LCFR

Questions about AST GMP 025? Our team of adhesive specialists can help. Submit your questions and we'll get you answers right away.